Exhaust Removal and Air Filtration Systems Defined

The Most Advanced Technology Available

There are several technology options available to remove vehicle exhaust emissions: Source Capture Systems, Diesel Particulate Filter, Air Cleaning Systems and Simple Drop Systems. Each system is explained below. The MagneGrip Exhaust Removal Systems offer the most advanced technology available for exhaust removal. Tested and proven in thousands of applications, the unique features of MagneGrip Exhaust Removal Systems make them the first choice among firefighters.

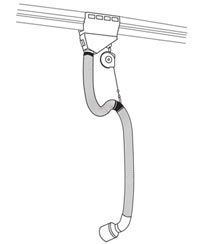

Source Capture Systems

This type of system uses a hose and nozzle, a rail or track with a movable trolley or expandable flexhose, ductwork, and an exhaust fan to draw the vehicle exhaust emissions out of the firehouse. The nozzle connects to the vehicle exhaust pipe, making it the most effective way to eliminate hazardous diesel exhaust emissions “at the source.” When responding to an alarm, the system remains connected until the apparatus reaches the doorway, at which time the nozzle automatically releases.

Source capture systems use magnets in three different ways to connect the nozzle:

1. Magnetic-assisted (MagneGrip) – magnets support a mechanical connection and the nozzle releases when lifted at a set angle.

2. Magnetic grabber – magnets hold the nozzle onto the tailpipe and use a moving thrust-action to detach the nozzle;

3. Electro-magnetic – a magnetic plate on the hose attaches to the side of the apparatus, holding the nozzle over the tailpipe. Electric wiring must carry current along the track and down the hose to trigger the release when exiting.

Pneumatic systems are an older source-capture method of placing a rubber bladder over the tailpipe and then inflating the bladder. This requires running an air hose from an operating compressor along the rail and down the side of the flexible hose. The nozzle release occurs when a mechanism is tripped causing the bladder to deflate and fall away.

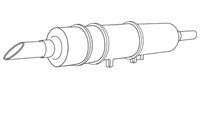

Diesel Particulate Filter

This is an underbody, canister-type filter that manufacturers install on apparatus beginning with 2007 models, as mandated by the EPA. These filters can also be purchased for the older model apparatus. The filter’s primary purpose is to capture the particulate that is at its greatest concentration when a vehicle is started. The filters may also capture some gases, but underbody filtration technology is not capable of eliminating most of the toxic gases and fine particulate in diesel exhaust emissions.

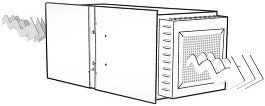

Air Cleaning Systems

These systems use a series of ceiling-mounted air filtration units in the bay area to pull in exhaust fumes and other pollutants. The systems are set to operate automatically. Contaminated air is drawn through a series of filters to trap particulates and gases, and then the cleaned air is dispersed back into the facility. The two primary types of air circulation patterns used in air cleaning devices are vertical and horizontal patterns. Vertical air circulation pulls in contaminated air at the base of each unit and sends filtered air out from the top. Horizontal air circulation pulls in contaminated air at one end of the unit and sends filtered air out the other end to create a continuous pattern of filtration. A photo-catalytic oxidizer can be used as the fourth stage of filtration in some air-cleaning devices for additional protection. The PCO contains ultraviolet lamps and a specially coated grid to neutralize toxic compounds such as carbon monoxide and nitrous oxide. The UV lamps kill airborne contaminants such as viruses, bacteria and mold spores. Other types of air filtration devices, such as ducted and portable units, may be used in other parts of a facility, such as turnout gear rooms, living quarters and offices.

Why Is a MagneGrip Exhaust Removal System Your Best Choice?

Cooler Operation

Only MagneGrip offers a patented 100% sealed system that allows for ambient air intake to cool hot exhaust emissions. Our patented nozzle has a one-way check valve that allows air in but does not allow exhaust fumes to escape. The air intake cools the exhaust, reduces wear and extends the life of the system’s components.

Automatic Release

MagneGrip’s patented, magnetic-assisted nozzle has three Magne-Paks (with rare-earth magnets) strategically located to support the nozzle connection. Guide pins ensure that the nozzle is always properly connected. When the vehicle exits the bay, a cable inside the hose causes a positive release of the nozzle at the door. The cable eliminates tension or pull on the hose, so it is less likely to stretch over time.

Less Equipment

Competitive pneumatic and electro-magnetic systems require extra equipment such as air compressors that cycle on and off 24 hours a day to maintain pressure, air lines running from the compressor all the way to a control valve, electro-magnetic wiring that is necessary to release attachment to the vehicle, etc. MagneGrip systems do not require this extra equipment.

No Safety-Disconnect Needed

MagneGrip is so confident its nozzle will release automatically with every exit, a safety-disconnect is not required. After releasing at the door, the hose/nozzle assembly safely retracts away from the door. Competitive systems need a safety-disconnect because the nozzle doesn’t always release when exiting. When this occurs, the apparatus drags the lower hose section down the street with the nozzle still attached.

Continuous Operation Even During Power Outages

If the power is out in your station, the MagneGrip system continues to operate and the nozzle automatically releases at the door. With pneumatic or electro-magnetic systems, when there is no power or a delay in power, there is no automatic release and your emergency response time can be compromised.

"We looked at the different systems, and MagneGrip's operation is extremely easy. Unlike other systems, the MagneGrip system has very little maintenance." - Randy Rigsby, Chief, Berea (KY) F.D.

Share On: